Is a Powder Coating Machine User-Friendly?

The realm of industrial finishes has long heralded the advent of powder coating as a superior alternative to traditional painting techniques. With its resilience, eco-friendliness, and cost-efficiency, the powder coating machine has become a staple in many manufacturing processes. But one question that often surfaces for businesses considering the leap to this technology is: Are these machines user-friendly? Let’s unpack the user experience of operating a powder coating machine through various lenses, from interface to support.

User Interface and Controls

A primary factor in the user-friendliness of any equipment is the intuitiveness of its interface and controls. Industrial powder coating ovens and machines are engineered with the end-user in mind, often featuring touch-screen interfaces and logically arranged control panels. While the complexity of the machine can vary depending on its capabilities and features, manufacturers are increasingly leaning towards more navigable control schemes. Operators can typically manage the powder flow, curing time, and temperature settings with relative ease, allowing for precise application and consistent quality in the coating process.

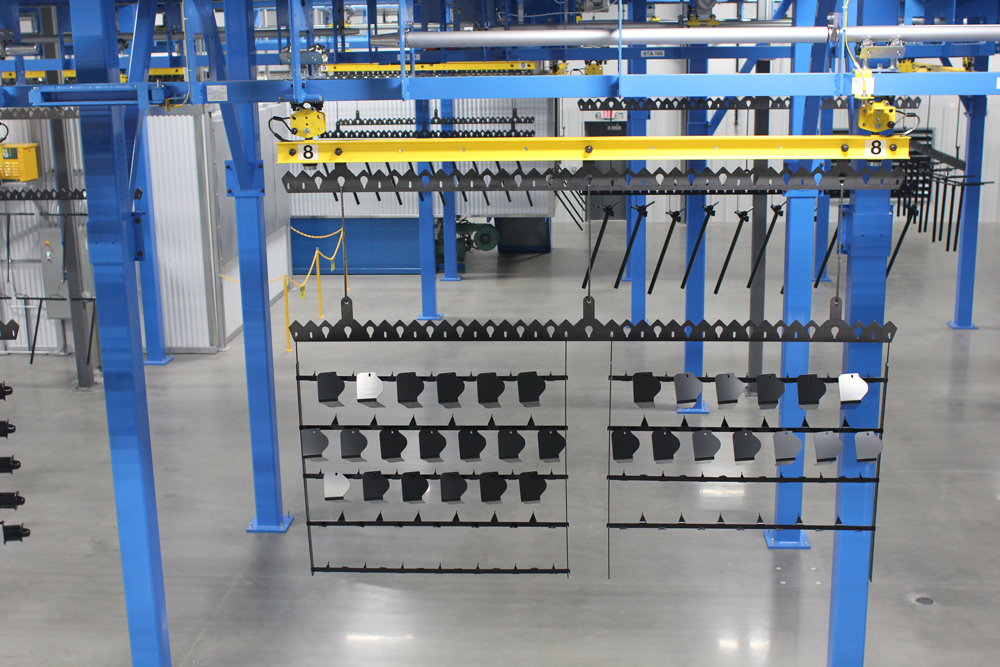

Ease of Operation

When considering ease of operation, powder coating machines score highly for their straightforward process: load the item, coat it, and cure it. The transition from traditional liquid painting to powder coating could feel like a quantum leap in operational efficiency. Many machines come equipped with automated systems that streamline the process. For example, an industrial oven tailored for powder coating ensures even curing, a critical step that’s almost carefree for the operator. The inherent design of these machines minimizes the manual labor required, reducing the strain on the operator and increasing productivity.

Learning Curve

Introducing any new machinery to a production line comes with a learning curve. However, modern powder coating machines are designed with the operator’s learning journey in mind. New models often come with on-board guidance, providing step-by-step instructions for the various processes involved. While the initial setup and operation of a powder coating machine may take some getting used to, especially for those transitioning from other methods, the learning curve is not steep. With well-structured training, operators can quickly become proficient in using the equipment.

Maintenance and Cleaning

Maintenance is where powder coating machines truly shine in terms of user-friendliness. They typically require less upkeep than their liquid-based counterparts, mainly because there’s no drying of liquid paint, which can clog components. Cleaning is often a breeze; since powder does not stick to the machine parts as wet paint does, it can often be vacuumed or wiped away. Scheduled maintenance for an industrial powder coating oven and the machine itself usually involves checking the filters and ensuring the electrical components are functioning correctly. Adherence to a regular maintenance schedule can prevent most operational hitches.

Safety Features

Safety is paramount in any industrial setting, and powder coating machines come equipped with numerous features to protect operators. Interlocks, emergency stops, and thermal cutoffs are standard inclusions. These safety measures ensure that the machine poses minimal risk to its users when operated according to the guidelines. Furthermore, the nature of powder coating—free from volatile organic compounds that are present in liquid paints—adds an inherent health advantage to its use.

Technical Support and Training

No machine can be considered user-friendly if it leaves its operators in the lurch post-purchase. Recognizing this, manufacturers of powder coating machinery often offer comprehensive technical support and training programs. This support can range from on-site training sessions upon installation to 24/7 customer service helplines and online troubleshooting guides. Ensuring that operators are well-versed in the machinery’s operation and have access to assistance when needed is essential for a seamless, user-friendly experience.

User Feedback and Reviews

Lastly, the real test of user-friendliness can be found in the feedback and reviews from actual users of powder coating machines. Many businesses report a positive experience, noting the machines’ efficiency, the high quality of the finish, and the simplicity of the powder coating process. Positive critiques often highlight the reliability and longevity of industrial ovens and the noticeable difference in the ease of operation compared to other industrial finishing methods.

In conclusion, with thoughtful design considerations focusing on the user experience, powder coating machines prove to be user-friendly, efficient, and an advantageous addition to an industrial environment. Their easy-to-navigate interfaces, streamlined operation processes, manageable learning curves, simple maintenance, robust safety features, solid technical support, and favorable user feedback make them a compelling choice for businesses looking to optimize their finishing processes. As technology progresses, we can only anticipate these machines to become even more operator-centric, further easing their integration into industrial workspaces.